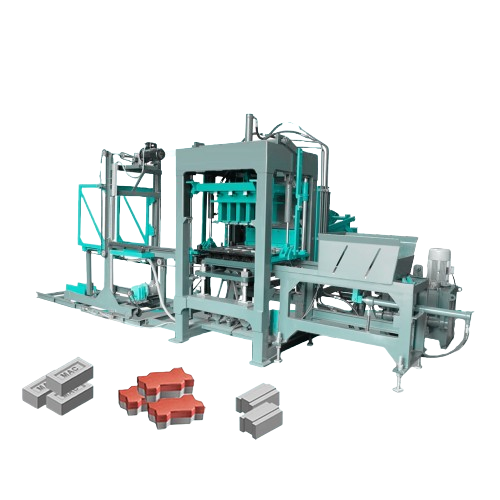

A fully automated machine designed for high-pressure production of fly ash bricks efficiently.

-

Plot No. 22, NK3 Industrial Park, Bakrol-Gatrad Road, Opp. Redbricks Batti, Bakrol,Bujrang,Ahmedabad-382430, Gujarat

- Plot No. 22, NK3 Industrial Park, Bakrol-Gatrad Road, Opp. Redbricks Batti, Bakrol, Bujrang, Ahmedabad-382430, Gujarat.

-

sales@skymacindustries.insales@skymacindustries.in

-

+91 76000 09512+91 76000 09512

Fully Automatic Fly Ash Brick Making Machine

Technical Specs

No

Property

HP/Cap.

1

Capacity

4000 Bricks per Day

2

Automation Grade

Vibro-Hydro Machine ( Fully Automatic -Multipurpose)

3

Brick Type

Solid

4

Machine Type

Hydraulic Pressure

5

Cavity

4 to 8

6

Max. Product weight

7

Machine Type

8

Hydraulic Oil Cap.

9

Material Compaction System

10

Required Shed Area

Production Capacity

Solid Blocks

Pcs/Per Day: 2000

Solid Blocks

Dimensions: 190 mm x 90 mm x 90 mm

203 mm x 92 mm x 57 mm

203 mm x 92 mm x 57 mm

Hollow Blocks

Pcs/Per Day: 2000

Hollow Blocks

Dimensions: 390 mm x 190 mm x 190 mm

400 mm x 200 mm x 200 mm (approx. 16 in x 8 in x 8 in)

400 mm x 200 mm x 200 mm (approx. 16 in x 8 in x 8 in)

Paver Blocks

Pcs/Per Day: 2000

Paver Blocks

Dimensions: 200 mm x 100 mm x 60 mm

100 mm x 100 mm x 60 mm

100 mm x 100 mm x 60 mm

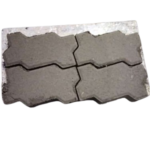

Interlocking Blocks

Pcs/Per Day: 2000

Interlocking Blocks

Dimensions: 200 mm x 100 mm x 60 mm

200 mm x 200 mm x 80 mm

200 mm x 200 mm x 80 mm

Curve stone

Pcs/Per Day: 2000

Curve stone

Dimensions: 915 mm x 150 mm x 300 mm

1000 mm x 250 mm x 300 mm

1000 mm x 250 mm x 300 mm

Cement Blocks

Pcs/Per Day: 2000

Cement Blocks

Dimensions: 915 mm x 150 mm x 300 mm

1000 mm x 250 mm x 300 mm

1000 mm x 250 mm x 300 mm

CONCRETE PRODUCT TYPES

All our Fly Ash Brick Making Machines can produce bricks of any shape and sizes including the following commonly used shapes

Skymac - GALLERY

p

p

p

p

p

Why choose us

Manufacturing & factory.

The production capacity of this machine typically ranges from 3,000 to 10,000 bricks per hour, depending on the specific model and operational settings. Its high efficiency makes it suitable for large-scale production.

The high-pressure system ensures that bricks are produced with greater density, strength, and uniformity. The fully automatic nature of the machine minimizes manual labor, reduces human error, and increases production speed, ensuring consistent quality in every batch.

The machine can produce a wide range of bricks, including solid bricks, hollow bricks, paver blocks, and interlocking bricks. The machine's molds can be customized to produce different shapes, sizes, and patterns according to specific requirements.

The machine typically requires an electrical power supply ranging from 30 to 50 HP (Horsepower), depending on the model and the production capacity. A stable and consistent power supply is crucial for its operation.

The fully automatic machine is equipped with automated feeders and mixers that handle the raw materials (fly ash, sand, cement, and water) with precision. The materials are automatically fed into the machine, mixed, and pressed under high pressure to form the bricks.

Regular maintenance includes checking and maintaining hydraulic systems, ensuring that electrical components and sensors are functioning correctly, lubricating moving parts, and cleaning the machine after use. Scheduled professional servicing is recommended to keep the machine running efficiently and to extend its operational life.